When working with electrical systems, safety is paramount, and having the right tool that checks for electrical current is crucial. Whether you're a professional electrician or a DIY enthusiast, understanding the importance of these tools can make all the difference in ensuring your safety and efficiency. Modern electrical testing tools are designed to provide accurate readings, helping you identify potential hazards before they escalate into serious issues. These devices come in various forms, each tailored to specific needs, ranging from simple voltage testers to advanced multimeters. Knowing how to select and use the appropriate tool that checks for electrical current can significantly enhance your productivity and peace of mind.

Electrical current testing tools are essential for anyone dealing with electrical systems, whether residential, commercial, or industrial. With the rise in demand for energy-efficient solutions and smart home technologies, the need for accurate testing tools has never been more critical. These devices not only help detect electrical faults but also play a vital role in maintaining system efficiency and preventing accidents. By investing in a quality tool that checks for electrical current, you can ensure compliance with safety standards while improving overall performance.

As technology continues to evolve, so do the capabilities of electrical testing tools. Innovations in design and functionality have made these devices more user-friendly and reliable than ever before. From non-contact voltage testers that allow you to detect live wires without touching them to advanced digital multimeters capable of measuring multiple parameters, the options available today cater to a wide range of needs. This guide will explore the different types of tools, their features, and how to choose the right one for your specific requirements.

Read also:Rambo Cast Unveiling The Legendary Ensemble That Defined Action Cinema

What Are the Most Common Types of Tool That Checks for Electrical Current?

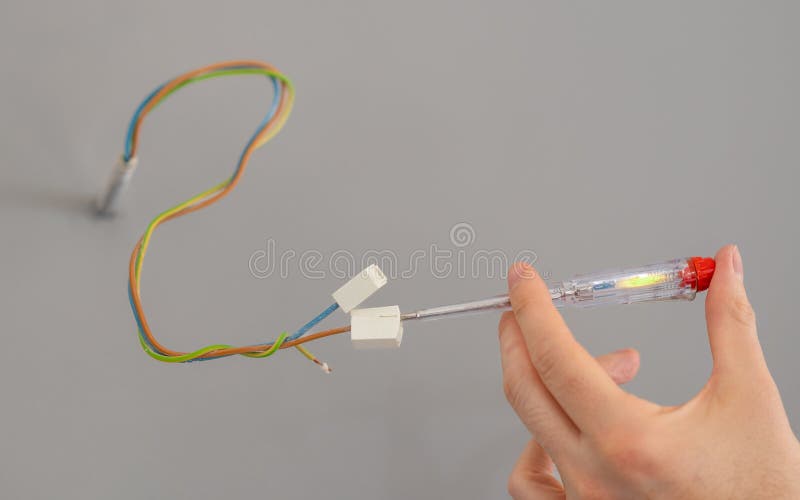

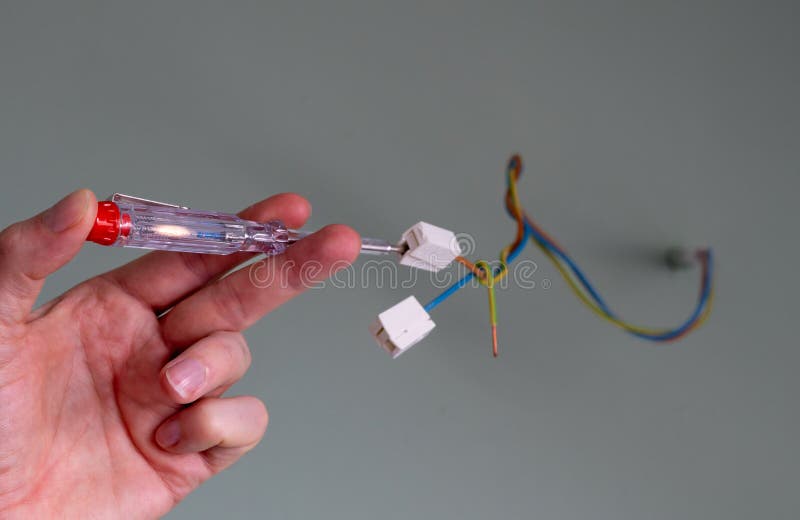

There are several types of electrical testing tools available, each designed for specific purposes. The most common ones include non-contact voltage testers, digital multimeters, clamp meters, and continuity testers. Non-contact voltage testers are ideal for quick checks, allowing you to detect voltage without making direct contact with the circuit. Digital multimeters, on the other hand, offer a more comprehensive approach, enabling you to measure voltage, current, and resistance. Clamp meters are particularly useful for measuring high current levels, while continuity testers help verify the integrity of electrical connections.

How Do You Choose the Right Tool That Checks for Electrical Current?

Selecting the appropriate tool depends on several factors, including the nature of your work, the level of accuracy required, and your budget. For instance, if you're primarily working on low-voltage circuits, a simple non-contact voltage tester might suffice. However, for more complex tasks involving high-voltage systems, a digital multimeter with advanced safety features would be more suitable. Additionally, consider the durability and ease of use of the tool, as well as any additional features that could enhance its functionality, such as auto-ranging or data logging capabilities.

Why Is It Important to Use a Tool That Checks for Electrical Current?

Using the right tool that checks for electrical current is crucial for ensuring safety and efficiency. Electrical systems can be unpredictable, and failing to detect hidden faults can lead to severe consequences, including electrical fires or equipment damage. By employing a reliable testing tool, you can identify potential issues early, preventing them from escalating into major problems. Moreover, these tools help maintain compliance with safety regulations, protecting both you and others from potential hazards.

What Are the Key Features to Look for in a Tool That Checks for Electrical Current?

When evaluating electrical testing tools, pay attention to key features that can enhance their performance and usability. These include accuracy, range, resolution, and safety ratings. Accuracy ensures that the readings provided are reliable, while range determines the extent of measurements the tool can handle. Resolution refers to the smallest increment the tool can detect, and safety ratings indicate the level of protection it offers against electrical hazards. Other important features to consider include backlight displays for better visibility, ergonomic design for comfort, and robust construction for durability.

What Are the Benefits of Using a Non-Contact Voltage Tester as a Tool That Checks for Electrical Current?

Non-contact voltage testers offer several advantages, making them a popular choice among professionals and DIY enthusiasts alike. Firstly, they provide a quick and easy way to detect live wires without physical contact, reducing the risk of electric shock. Secondly, they are compact and lightweight, making them convenient to carry around. Additionally, many models come with additional features such as LED indicators and audible alarms, enhancing their usability. However, it's important to note that these testers are primarily designed for voltage detection and may not be suitable for more complex tasks.

Which Tool That Checks for Electrical Current Is Best for High-Voltage Systems?

For high-voltage systems, a clamp meter or an advanced digital multimeter is often the best choice. Clamp meters are specifically designed to measure large currents without interrupting the circuit, making them ideal for industrial applications. They typically feature larger jaw openings to accommodate thicker wires and offer a wide measurement range. Digital multimeters, on the other hand, provide greater versatility, allowing you to measure multiple parameters accurately. When selecting a tool for high-voltage systems, prioritize safety features such as insulated handles, overvoltage protection, and high CAT ratings.

Read also:Unveiling Tonights Snl Host A Comprehensive Guide To Whos Hosting Snl Tonight

How Can You Maintain and Calibrate Your Tool That Checks for Electrical Current?

Regular maintenance and calibration are essential for ensuring the accuracy and longevity of your electrical testing tool. Start by cleaning the tool after each use, removing any dirt or debris that could affect its performance. Store it in a dry, secure location to prevent damage from moisture or impact. Calibration should be performed periodically, either by the manufacturer or an authorized service provider, to ensure the tool remains within acceptable tolerances. Following the manufacturer's guidelines for maintenance and calibration will help maximize the tool's lifespan and reliability.

What Are the Safety Precautions When Using a Tool That Checks for Electrical Current?

Safety should always be a top priority when working with electrical systems. Before using any testing tool, familiarize yourself with its operation manual and safety instructions. Wear appropriate personal protective equipment (PPE), such as insulated gloves and safety goggles, to minimize the risk of electric shock. Ensure the tool is properly rated for the voltage and current levels you'll be working with, and never exceed its specified limits. Additionally, avoid using damaged tools and regularly inspect them for signs of wear or malfunction.

Can a Tool That Checks for Electrical Current Be Used for Both AC and DC Systems?

Many modern electrical testing tools are designed to handle both AC and DC systems, offering greater versatility for various applications. However, it's important to verify the tool's specifications to ensure it supports the type of current you'll be working with. Some tools may have separate modes or settings for AC and DC measurements, while others may require different probes or accessories. Always check the tool's compatibility with your specific needs to avoid potential inaccuracies or damage.

Conclusion: Why Invest in a Quality Tool That Checks for Electrical Current?

In conclusion, investing in a high-quality tool that checks for electrical current is essential for anyone working with electrical systems. These tools not only enhance safety but also improve efficiency and accuracy, helping you perform your tasks with confidence. By understanding the different types of tools available, their features, and how to use them properly, you can make an informed decision that meets your specific needs. Remember to prioritize safety, maintenance, and regular calibration to ensure optimal performance and longevity of your testing tool.

Table of Contents

- Introduction

- What Are the Most Common Types of Tool That Checks for Electrical Current?

- How Do You Choose the Right Tool That Checks for Electrical Current?

- Why Is It Important to Use a Tool That Checks for Electrical Current?

- What Are the Key Features to Look for in a Tool That Checks for Electrical Current?

- What Are the Benefits of Using a Non-Contact Voltage Tester as a Tool That Checks for Electrical Current?

- Which Tool That Checks for Electrical Current Is Best for High-Voltage Systems?

- How Can You Maintain and Calibrate Your Tool That Checks for Electrical Current?

- What Are the Safety Precautions When Using a Tool That Checks for Electrical Current?

- Can a Tool That Checks for Electrical Current Be Used for Both AC and DC Systems?